The machine condition monitoring market has emerged as a critical enabler of predictive maintenance, helping industries minimize downtime, increase productivity, and extend equipment lifespan. In today’s competitive manufacturing and industrial landscape, even minor equipment failure can result in significant financial losses. Machine condition monitoring offers a proactive approach to managing mechanical assets, using data and real-time insights to detect anomalies before they escalate into failures.

With the rise of Industry 4.0 and industrial automation, the machine condition monitoring market is experiencing robust growth. Technologies such as IoT, artificial intelligence (AI), and wireless sensors are fueling advancements, making condition monitoring systems more intelligent, cost-effective, and scalable across various industries.

Understanding Machine Condition Monitoring

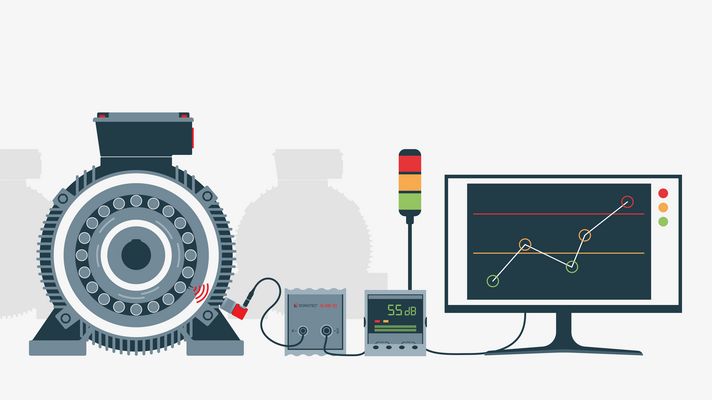

Machine condition monitoring refers to the process of tracking various parameters of machinery—such as vibration, temperature, noise, oil quality, and pressure—to assess the health and performance of equipment. These metrics help detect early signs of mechanical degradation, misalignment, wear, or failure.

Monitoring methods can be either periodic or continuous. Periodic monitoring involves manual or scheduled inspections, while continuous monitoring uses integrated systems and real-time data analytics for round-the-clock surveillance.

Market Overview

The global machine condition monitoring market is expected to grow at a significant CAGR over the coming years. This growth is driven by the increasing demand for predictive maintenance solutions across industries such as manufacturing, energy, oil & gas, aerospace, transportation, and power generation.

North America currently leads the market due to early adoption of smart manufacturing solutions and a strong presence of key technology providers. However, Asia-Pacific is witnessing rapid growth, driven by industrialization, infrastructural development, and expanding manufacturing bases in China, India, and Southeast Asia.

Key Market Drivers

1. Rise in Predictive Maintenance Strategies

Companies are shifting from reactive or scheduled maintenance to predictive maintenance to reduce equipment failure, lower maintenance costs, and optimize operational efficiency.

2. Integration with IoT and Smart Sensors

The incorporation of IoT-enabled devices and smart sensors has revolutionized condition monitoring by enabling remote diagnostics, real-time alerts, and seamless data integration.

3. Increasing Focus on Operational Efficiency

Industries are under pressure to boost asset performance while minimizing energy consumption and environmental impact, making condition monitoring essential.

4. Cost Reduction and ROI

Although initial setup costs for monitoring systems can be high, the return on investment through reduced downtime and maintenance expenses is substantial.

5. Regulatory Compliance and Safety

Monitoring systems help ensure compliance with safety regulations and standards by continuously evaluating machinery performance and identifying hazards.

Market Segmentation

The machine condition monitoring market can be segmented by:

Monitoring Technique: Vibration monitoring, thermography, oil analysis, corrosion monitoring, ultrasound emission

Component: Hardware (sensors, analyzers), software, services

Deployment Mode: On-premise, cloud-based, hybrid

End-Use Industry: Manufacturing, oil & gas, aerospace, power generation, mining, transportation

Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Vibration monitoring continues to dominate the market due to its effectiveness in detecting misalignment and imbalance in rotating machinery.

Technological Trends

Edge Computing in Monitoring Devices: Enables real-time data processing at the source for faster decision-making

AI and Machine Learning Algorithms: Used for anomaly detection and predictive analytics

Cloud-based Platforms: Allow centralized monitoring of multiple assets across different locations

Wireless Monitoring Solutions: Offer flexibility and reduce installation costs, especially in remote or complex environments

Digital Twin Technology: Simulates asset performance to predict failures and optimize operations

Challenges in the Market

Despite the many benefits, the machine condition monitoring market faces several challenges:

High Initial Costs: Upfront investment for hardware, installation, and training can be a deterrent for small and medium enterprises

Data Management: Handling and analyzing massive volumes of data from multiple sensors can be complex

Lack of Skilled Workforce: Operating and maintaining advanced condition monitoring systems requires specialized skills

Integration Issues: Compatibility with legacy systems can limit deployment

However, advancements in user-friendly software interfaces, plug-and-play solutions, and remote support are gradually addressing these issues.

Key Market Players

Some of the leading players in the machine condition monitoring market include:

Emerson Electric Co.

SKF Group

General Electric Company

National Instruments Corporation

Honeywell International Inc.

Rockwell Automation, Inc.

Schaeffler Technologies AG & Co. KG

Parker Hannifin Corporation

Siemens AG

Analog Devices, Inc.

These companies are investing heavily in R&D, partnerships, and acquisitions to expand their product portfolios and enhance their global presence.

Future Outlook

The machine condition monitoring market is poised for significant growth, driven by the convergence of mechanical engineering with digital technologies. As industries continue to digitize and demand greater asset reliability, condition monitoring will become a central pillar of predictive maintenance strategies.

With evolving standards, increasing emphasis on sustainability, and the adoption of smart factory principles, machine condition monitoring systems are not just optional tools but essential assets in the modern industrial landscape.

Stakeholders who invest in scalable, AI-powered, and integrated monitoring solutions will be better positioned to lead in the era of intelligent maintenance and Industry 4.0.