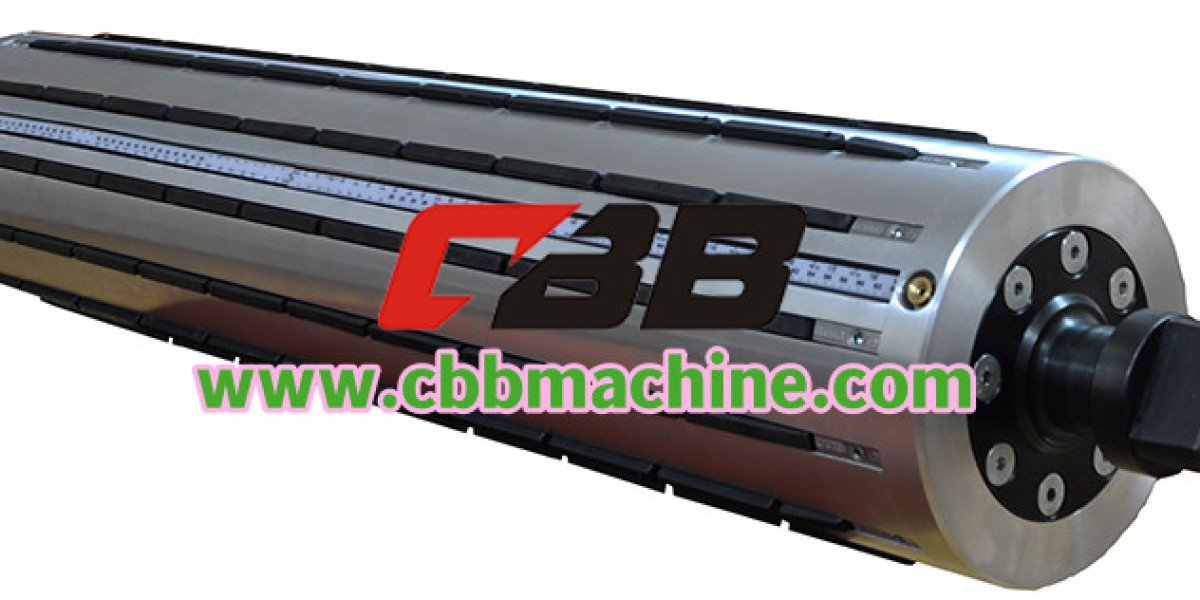

In the competitive landscape of industrial manufacturing, CBBMachine stands as a global leader among Differential Shaft manufacturers , delivering precision-engineered components that optimize torque control, durability, and operational efficiency. Specializing in applications ranging from automotive systems to renewable energy infrastructure, CBBMachine’s solutions empower industries to achieve peak performance while minimizing downtime and energy consumption.

Modern machinery demands components capable of withstanding dynamic loads and variable operational stresses. Traditional shafts often face challenges like misalignment, material fatigue, or inefficient power transmission. CBBMachine addresses these issues through advanced metallurgical innovations and AI-enhanced design processes, ensuring differential shafts achieve tolerances within 0.05mm. This precision reduces vibration-related wear by up to 40%, significantly extending equipment lifespan—a critical advantage for industries like wind energy and heavy machinery.

Sustainability is central to CBBMachine’s manufacturing ethos. By utilizing recycled alloys and energy-efficient production techniques, the company reduces carbon emissions by 25% compared to conventional methods. These practices align with global certifications such as ISO 50001, enabling clients to meet environmental goals without compromising productivity.

Customization further distinguishes CBBMachine’s expertise. Engineers collaborate with clients to tailor shaft specifications—adjusting load capacities, surface coatings, or connectivity interfaces—to suit unique operational needs. For example, in electric vehicle drivetrains, customized shafts enhance energy efficiency, while in mining equipment, reinforced designs withstand extreme conditions. Modular architectures ensure compatibility with both legacy systems and smart factories.

Beyond product excellence, CBBMachine offers comprehensive support, including IoT-driven predictive maintenance and 24/7 technical assistance. Real-time monitoring tools preemptively identify potential failures, reducing unplanned downtime by up to 50%.

For industries seeking reliability and innovation, CBBMachine’s differential shafts are engineered to drive tomorrow’s progress.

Discover CBBMachine’s cutting-edge solutions at www.cbbmachine.com precision meets industrial ambition.